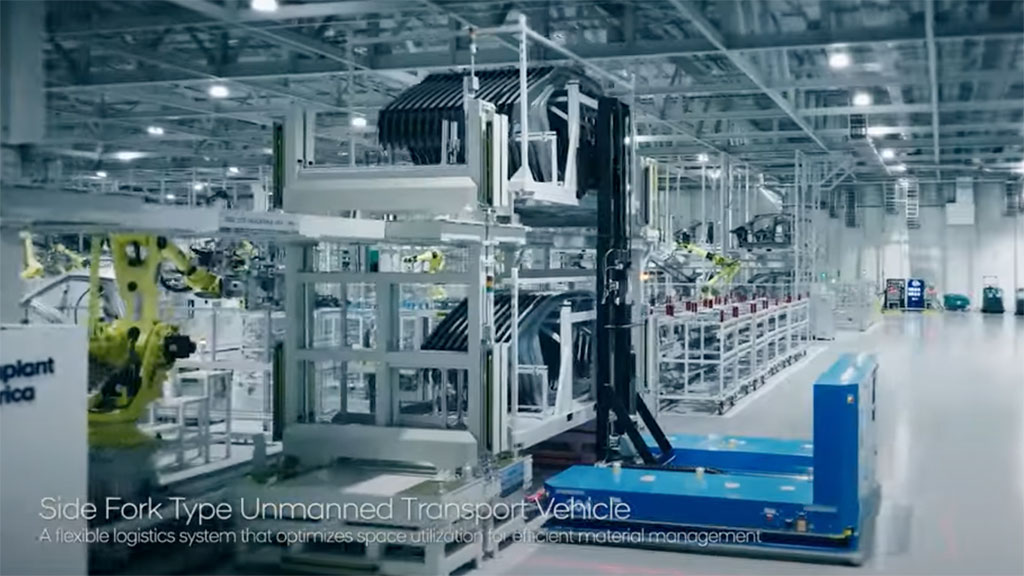

Hyundai has launched its most advanced manufacturing plant in the U.S., driven by AI and private 5G technology. The $7.6 billion HMG Metaplant America in Georgia combines cutting-edge automation with high-speed connectivity, setting new standards in Industry 4.0 innovation. Built to produce electric and hybrid vehicles, the facility will scale to 500,000 units annually by 2031. This project forms part of Hyundai’s $20.5 billion U.S. investment, with another $21 billion planned by 2031.

The new plant integrates artificial intelligence, private 5G networks, and robotics to enhance productivity and reduce manual labor. It represents the most telecom-integrated auto factory in North America. With its forward-thinking design and massive scope, it’s a clear signal of how telecom infrastructure and smart manufacturing are converging in the U.S. industrial landscape.

A Telecom-Powered Leap in Smart Manufacturing

Hyundai’s Metaplant America is the most connected and automated vehicle plant in the U.S. Leveraging AI vision systems and private 5G, it offers real-time control over industrial robotics and automation. Every vehicle function is streamlined using smart sensors, AI-driven software, and ultra-low latency connectivity.

The telecom integration is led by Georgia-based Future Technologies, which implemented Nokia’s private 5G core and radio access network. Their engineers designed the private network to support industrial automation and autonomous robotics. These include mobile robots, automated guided vehicles, and drones, all controlled through this advanced wireless infrastructure.

Industry 4.0 Innovation at Full Scale

Inspired by Hyundai’s Innovation Center in Singapore, this U.S. facility expands those solutions to a mega-factory scale. While human oversight remains critical, the automation systems handle most tasks. AI software processes sensor data, controls machines, and optimizes assembly processes.

Interestingly, while 5G powers many operations, it goes unmentioned in Hyundai’s press materials. The focus instead is on smart automation, AI vision, and digital transformation. Despite this, the network’s role is essential, supporting fully automated and semi-autonomous systems at an unprecedented scale.

A Telecom Blueprint for the Future

This facility sets a benchmark for how telecom and industrial sectors can collaborate to drive economic and technological growth. With a planned capacity of 500,000 vehicles per year and 8,500 full-time jobs by 2031, the impact is significant. The deployment of private 5G creates a roadmap for other manufacturers seeking automation at scale.

Though generative and agentic AI are not yet in use, the groundwork is laid. This plant may become the first U.S. facility to adopt next-gen AI applications, supported by advanced telecom architecture. As 5G networks evolve, their role in smart manufacturing will only deepen.